Viewmold company is one stainless steel investment casting and machining manufacturer in China. Our company machines custom

stainless steel casting compoents ranging from 0.05kg to 60kgs that match your exact design specifications.

Viewmold is plastic molding. and

metal machining supplier in China and committed to providing good quality custom metal parts for global customers.

In order to meet up customer's more requirements, our company set up modern stainless steel casting fabrication room in 2009,

it is located in Shenzhen. The new room primarily engage in fabrication of custom stainless steel casting. The room has 1000 square meters, and more 50 precise machines.

We can machine more 20 sets stainless steel casing molds every month, and have ability to produce 2000 stainless steel casting parts every day.

Our engineers have rich experiences in stainless steel casting and drawing parts, the degree of parts accuracy reach 0.2-0.4mm.

Our machining services include Nickel plating, Cromium plating, Zinc plating, black oxidation, Electrostatic Spraying, Electro-polishing, Saponification / phosphatin, CNC machining,

Sand blast.

Our company provides mass production service for customer, also according to the customer's request to conduct an overall product design, proofing.

In the rapid changing market, if you are looking for a reliable supplier for your custom metal parts, our company will be your excel trustworthy partner.

Could you please contact us as sales@viewmold.com. Thank you!

SS Castings parts application area:

Stainless steel has special properties: it can resist heat, abrasion, and corrosion. Stainless steel casting process has flexible machining processes

for complex shape.So it can be used in a different range of industries and is cost-efficient way. The following is main usages of stainless steel casting parts:

1-Food industrial area:

Stainless steel castings are widely used in food machineries due to rust-preventing capabilities, it is not the corrosive nature of the food itself, so stainless steel casting components can be

cleared by faster and efficient way.Stainless steel casting components also doesn't expose any teate to food.The common grades are 304 and 316. 304 is the main level,

316 is used in the higher demands.

2–Pipe compoents:

Stainless steel casting components are available in flanges, heads,elbow, tee, bushing, close nipples, etc.

Our machining capability can meet any requirement like threads.

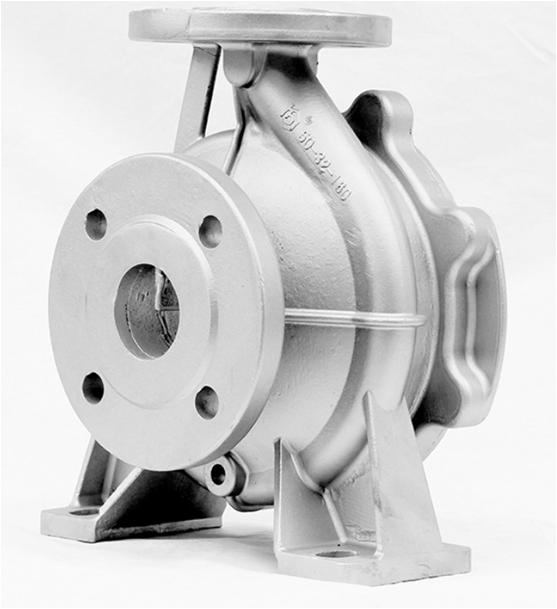

3–Pump and Components:

Common valve and pump components made from stainless steel casting include valve body, disc, bonnet, gland, pump body, etc.

4–Building and Construction

The current buildings use more stainless steel. It has low maintenance cost and anti-vandal characteristics and aesthetics. Especially the public construction market.

Stainless steel reinforcing bar, although initially expensive, is proving to have very good life cycle costing characteristics.

Material Grades of Stainless Steel Casting

304 The most widely used stainless steel.

304L Lower carbon content than 304 stainless steel,

316 The second most common stainless steel, SS316 is used primarily for its increased resistance to corrosion.

316L Lower carbon content than 316 stainless steel, the hardness is softer, it has better resistance to stress-corrosion cracking.

PH17-4 Most common precipitation-hardening martensitic stainless steel, it includes 17% chromium and 4% nickel.

2205 Duplex Used for its good mechanical properties and excellent corrosion resistance properties.

Linear Dimensional Tolerance (mm)

The following is post Treatments of Stainless Steel Casting components

1: Heat Treatment: like other steel castings, stainless steel castings may also require heat treatment to achieve a certain hardness and properties, the scope of heat treatment is from HRC20-55.

2:CNC Machining

3:Surface Treatments

Viewmold company is one stainless steel investment casting and machining manufacturer in China. Our company machines custom

stainless steel casting compoents ranging from 0.05kg to 60kgs that match your exact design specifications.

Viewmold is plastic molding. and

metal machining supplier in China and committed to providing good quality custom metal parts for global customers.

In order to meet up customer's more requirements, our company set up modern stainless steel casting fabrication room in 2009,

it is located in Shenzhen. The new room primarily engage in fabrication of custom stainless steel casting. The room has 1000 square meters, and more 50 precise machines.

We can machine more 20 sets stainless steel casing molds every month, and have ability to produce 2000 stainless steel casting parts every day.

Our engineers have rich experiences in stainless steel casting and drawing parts, the degree of parts accuracy reach 0.2-0.4mm.

Our machining services include Nickel plating, Cromium plating, Zinc plating, black oxidation, Electrostatic Spraying, Electro-polishing, Saponification / phosphatin, CNC machining,

Sand blast.

Our company provides mass production service for customer, also according to the customer's request to conduct an overall product design, proofing.

In the rapid changing market, if you are looking for a reliable supplier for your custom metal parts, our company will be your excel trustworthy partner.

Could you please contact us as sales@viewmold.com. Thank you!

SS Castings parts application area:

Stainless steel has special properties: it can resist heat, abrasion, and corrosion. Stainless steel casting process has flexible machining processes

for complex shape.So it can be used in a different range of industries and is cost-efficient way. The following is main usages of stainless steel casting parts:

1-Food industrial area:

Stainless steel castings are widely used in food machineries due to rust-preventing capabilities, it is not the corrosive nature of the food itself, so stainless steel casting components can be

cleared by faster and efficient way.Stainless steel casting components also doesn't expose any teate to food.The common grades are 304 and 316. 304 is the main level,

316 is used in the higher demands.

2–Pipe compoents:

Stainless steel casting components are available in flanges, heads,elbow, tee, bushing, close nipples, etc.

Our machining capability can meet any requirement like threads.

3–Pump and Components:

Common valve and pump components made from stainless steel casting include valve body, disc, bonnet, gland, pump body, etc.

4–Building and Construction

The current buildings use more stainless steel. It has low maintenance cost and anti-vandal characteristics and aesthetics. Especially the public construction market.

Stainless steel reinforcing bar, although initially expensive, is proving to have very good life cycle costing characteristics.

Material Grades of Stainless Steel Casting

304 The most widely used stainless steel.

304L Lower carbon content than 304 stainless steel,

316 The second most common stainless steel, SS316 is used primarily for its increased resistance to corrosion.

316L Lower carbon content than 316 stainless steel, the hardness is softer, it has better resistance to stress-corrosion cracking.

PH17-4 Most common precipitation-hardening martensitic stainless steel, it includes 17% chromium and 4% nickel.

2205 Duplex Used for its good mechanical properties and excellent corrosion resistance properties.

Linear Dimensional Tolerance (mm)

The following is post Treatments of Stainless Steel Casting components

1: Heat Treatment: like other steel castings, stainless steel castings may also require heat treatment to achieve a certain hardness and properties, the scope of heat treatment is from HRC20-55.

2:CNC Machining

3:Surface Treatments