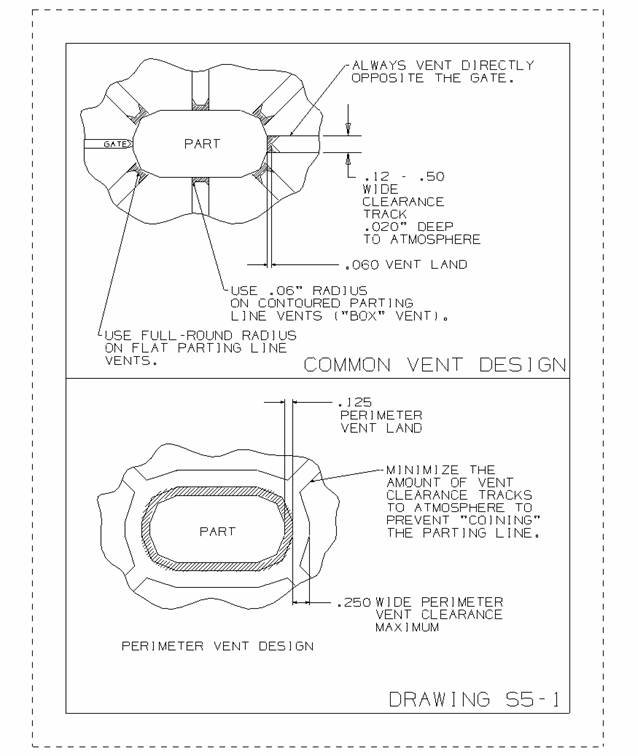

1) Vent land will be .06”. The vent clearance can be .12” - .50” wide x .02”

deep (refer to drawing S5-1) and are always routed to atmosphere. Vents are normally ground. Milled vents must be polished.

2) Perimeter vent land should be .125” minimum to .250” maximum.

3) Always vent directly opposite the gate and at all runner ends/cold well slugs.

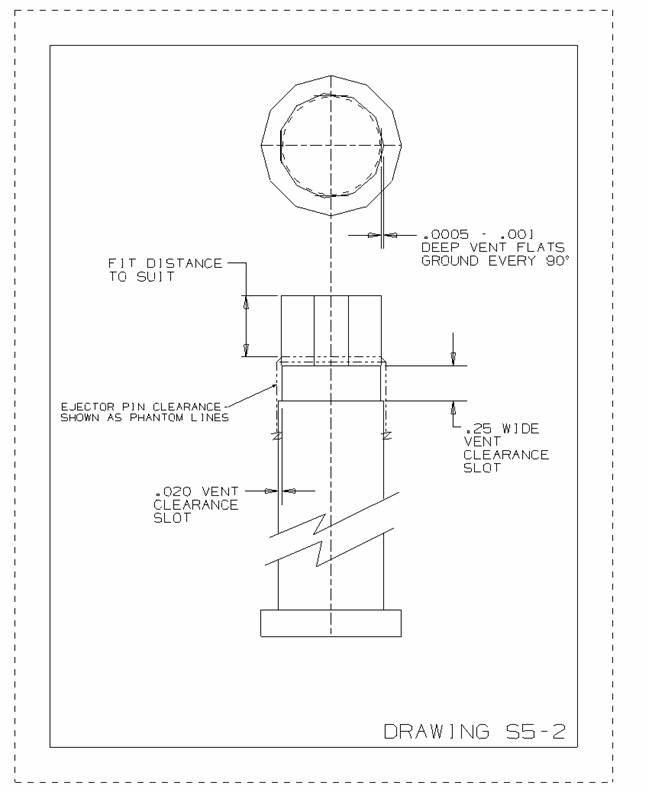

4) Ejector pin vents are sometimes necessary. Refer to drawing S5-2 for ejector pin vent design guidelines.

5) Common vent depths (INCHES):

ABS-------------------------------------- .001 - .0015

ACETAL-------------------------------- .0005 - .001

ACRYLIC-------------------------------.0015 - .002

CELLULOSE ACET, CAB-----------.001 - .0015

ETHYLENE VINYL ACET.---------.001 - .0015

IONOMER------------------------------.0005 - .001

LCP---------------------------------------.0005 - .0007

NYLON----------------------------------.0003 - .0005

PPO/PPS (NORYL)--------------------.001 - .002

POLYCARBONATE------------------.0015 - .0025

PET, PBT, POLYESTERS------------.0005 - .0007

POLYSULFONE-----------------------.001 - .002

POLYETHYLENE---------------------.0005 - .0012

POLYPROPYLENE-------------------.0005 - .0012

POLYSTYRENE-----------------------.0007 - .0012

HIGH IMPACT POLYSTYRENE---.0008 - .0012

PVC (RIGID)----------------------------.0006 - .001

PVC (FLEXIBLE)----------------------.0005-.0007

POLYURETHANE---------------------.0004 - .0008

SAN---------------------------------------.001 - .0015

T/P ELASTOMER----------------------.0005 - .0007

Injection Mold slide lifter standards

Injection Mold runner standards

Injection Mold cooling standards

Injection Mold venting standards

Injection Mold Ejector System standards standards

Injection Mold component standards

Injection Mold Hydraulic and Pneumatic standards

Injection Mold Design Check standards

Injection Mold Steel Grades standards

Injection Mold inspection standards