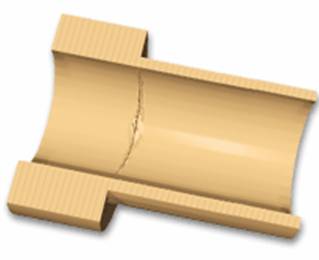

Definition

A brittle molded part has a tendency to break or crack. Brittleness results from shorter molecular

chain length (thus lower molecular weight). As a result, the physical integrity of the part is substantially less than the

specification.

Causes

Material degradation

This can be caused by excessive injection speed, residence time or melt temperature.

Improper screw or runner system design may also lead to material degradation.

Weld line weaknesses

Non-optimal crystallinity

High residual stress

Incompatible materials blended together

Too much regrind

Improper drying conditions

Excessive drying either drives off volatiles in the plastic, making it more sensitive to processing, or degrades the material by reducing the molecular weight.

Remedies

Set proper drying conditions before molding

Material suppliers can provide optimum drying conditions for the specific materials.

Reduce regrind material

Contact material suppliers to get the recommended levels of regrind to use.

Change material

Optimize the runner system design

Restrictive sprue, runner, gate, or even part design could cause excessive shear heating that aggravates an already overheated material, causing material degradation.

Modify screw design

Contact material/machine suppliers to get the right screw design information to avoid improper melt mix or overheating that leads to material degradation.

Select machine with smaller shot size

Minimizing residence time reduces material degradation.

Reduce residual stress

Strengthen weld lines

Increase melt temperature within limits, not to overheat the material.

Solving one problem can often introduce other problems to the injection molding process. Each option hence requires consideration of all relevant aspects of the mold design specification.

Injection Molding air trap issue and solution

Injection Molding brittleness issue and solution

Injection Molding burn issue and solution

Injection Molding crack issue and solution

Injection Molding delamination issue and solution

Injection Molding dimensional variation issue and solution

Injection Molding discoloration issue and solution

Injection Molding excessive part weight issue and solution

Injection Molding fish eye issue and solution

Injection Molding flash issue and solution

Injection Molding follow line issue and solution

Injection Molding hesitation issue and solution

Injection Molding high volumetric shrinkage issue and solution

Injection Molding jetting issue and solution

Injection Molding overpacking issue and solution

Injection Molding racetrack effect issue and solution

Injection Molding short shot issue and solution

Injection Molding sink mark and void issue and solution

Injection Molding unbalanced flow issue and solution

Injection Molding underflow issue and solution

Injection Molding warpage issue and solution

Injection Molding weld and meld line issue and solution