Definition

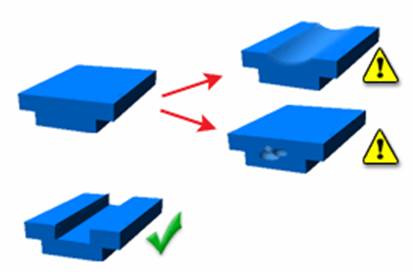

Sink marks and voids both result from localized shrinkage of the material at thick sections without

sufficient compensation.

Sink Marks

Sink marks appear as depressions on the surface of a molded part. These depressions are typically

very small; however they are often quite visible, because they reflect light in different directions to the part. The visibility of

sink marks is a function of the color of the part as well as its surface texture so depth is only one criterion. Although sink marks

do not affect part strength or function, they are perceived to be severe quality defects.

Voids

Voids are holes enclosed inside a part. These can be a single hole or a group of smaller holes.

Voids are caused when the outer skin of the part is stiff enough to resist the shrinkage forces thus preventing a surface depression.

Instead, the material core will shrink, creating voids inside the part. Voids may have severe impact on the structural performance

of the part.

Causes

Sink marks are caused mainly by thermal contraction (shrinkage) during cooling. After the material

on the outside has cooled and solidified, the core material starts to cool. Its shrinkage pulls the surface of the main wall inward,

causing a sink mark. If the skin is rigid enough, deformation of the skin may be replaced by formation of a void in the core.

Localized geometric features

sink marks typically occur in moldings with thicker sections, or at locations opposite from ribs,

bosses or internal fillets.

High volumetric shrinkage

Insufficient material compensation

Early gate freeze-off or low packing pressure may not pack the cavity properly.

Short packing or cooling time

High melt and/or mold temperatures

Remedies

Optimize packing profile

As sink marks occur during packing, the most effective way to reduce or eliminate them is to control

the packing pressure correctly. To determine the effects of packing on sink marks, use a simulation package such as Moldflow Plastics

Insight.

Change part geometry

Alter part design to avoid thick sections and reduce the thickness of any features that intersect

with the main surface.

Reduce volumetric shrinkage

Relocate gates to problem areas

This allows these sections to be packed before the thinner sections between the gate and the problem

areas freeze.

Optimize the runner system design

Restrictive runner system design can result in premature gate freeze-off.

Change material

Solving one problem can often introduce other problems to the injection molding process. Each option hence requires consideration of all relevant aspects of the mold design specification.

Injection Molding air trap issue and solution

Injection Molding brittleness issue and solution

Injection Molding burn issue and solution

Injection Molding crack issue and solution

Injection Molding delamination issue and solution

Injection Molding dimensional variation issue and solution

Injection Molding discoloration issue and solution

Injection Molding excessive part weight issue and solution

Injection Molding fish eye issue and solution

Injection Molding flash issue and solution

Injection Molding follow line issue and solution

Injection Molding hesitation issue and solution

Injection Molding high volumetric shrinkage issue and solution

Injection Molding jetting issue and solution

Injection Molding overpacking issue and solution

Injection Molding racetrack effect issue and solution

Injection Molding short shot issue and solution

Injection Molding sink mark and void issue and solution

Injection Molding unbalanced flow issue and solution

Injection Molding underflow issue and solution

Injection Molding warpage issue and solution

Injection Molding weld and meld line issue and solution