DME companys mold base standard has 4 main type:

1: American mold base standard, all dimensions of mold base and component adopt inch unit,

It is suitable for Amerian area.

2:Europen mold base standard, all dimensions of mold base and component adopt MM unit,

It is suitable for Europe area.

3:DME standard Small-Shuttle Mold Bases

4:DME Custom-Configured Mold Bases,DME Manufactures mold base as customers request,

but it is very expensive.

Our company manufatures mold base as DME or custom standard for global customers, all components of mold base adopt

DME standard,we finish all manufacturing of mold base that includes pockets, ejector holes, wateline holes, EJP, side lockes, slide slotes etc...

The following is the reasons why you need to select the DME standard bases

1. They are made of high quality, pre-finished mold and die steels that give you more for your money; more metallurgical consistency; more cleanliness In cavity steels; more reliability.

2. Assemblies, plates and components are pre-engineered to give you the economic and technical benefits of Interchangeability.

3. They are manufactured with the most advanced, precision equipment - and quality control tested to give you reliable performance.

4. They give designers more freedom and flexibility - more time to devote to the truly creative aspects of mold, die, and product design.

4. They give designers more freedom and flexibility - more time to devote to the truly creative aspects of mold, die, and product design.

5. They give mold and die makers more time to concentrate on cavities and cores - thus Increasing productivity as much as 403/8.

6. They give molders and die casters more quality parts per hour, more profitability - with production proven construction that outlasts the longest runs.

7. They are readily available as you need them. The more popular assemblies are always in stock for same-day service. Our nationwide network of Service

Centers means you have the products and the people near you to help you save time, money and inventory costs.

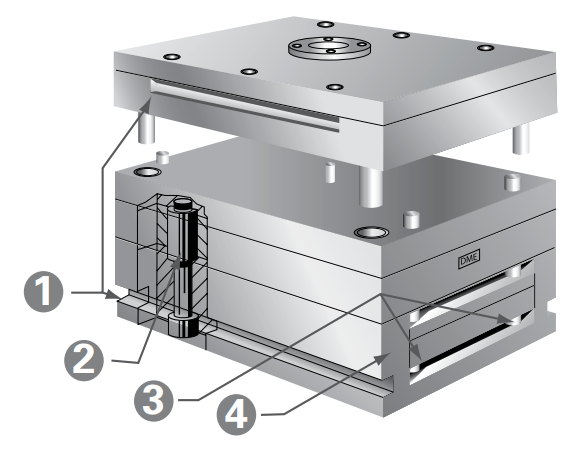

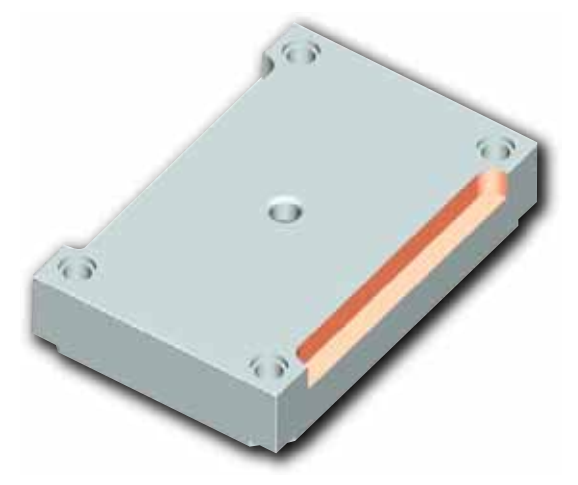

Standard DME Mold Bases have some special features:

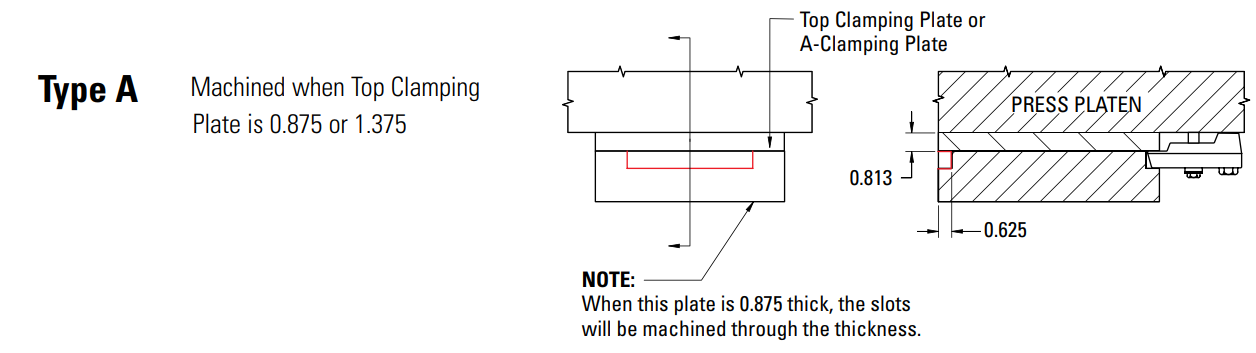

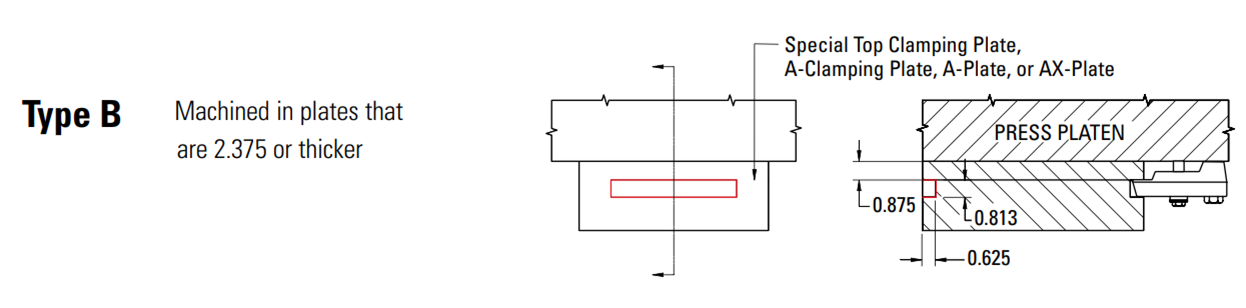

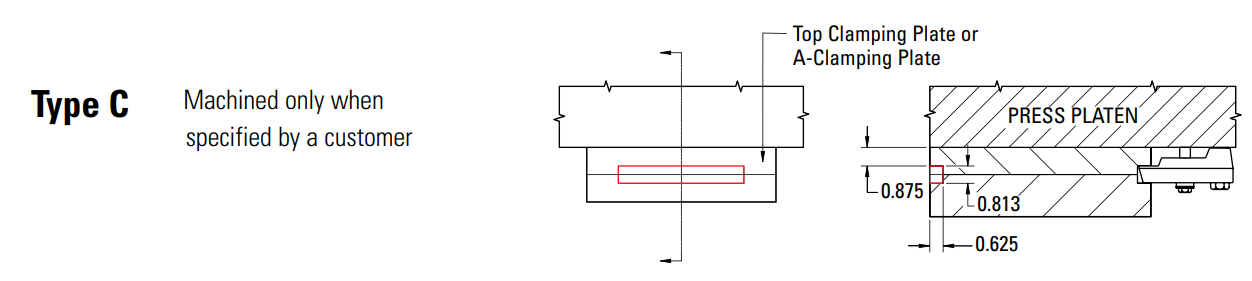

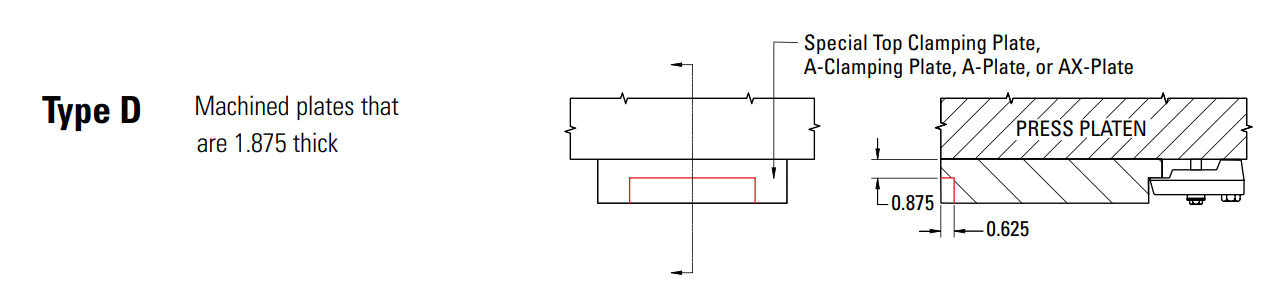

1 CLAMP SLOTS that save platen space and provide maximum cavity area

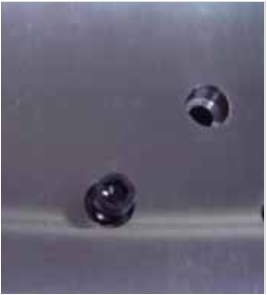

2 TUBULAR DOWELS that provide more room for waterlines

3 STOP PINS welded to ejector plate to prevent loosening and ejection interference

4 ONE-PIECE EJECTOR HOUSING that gives. added strength and simplifies construction

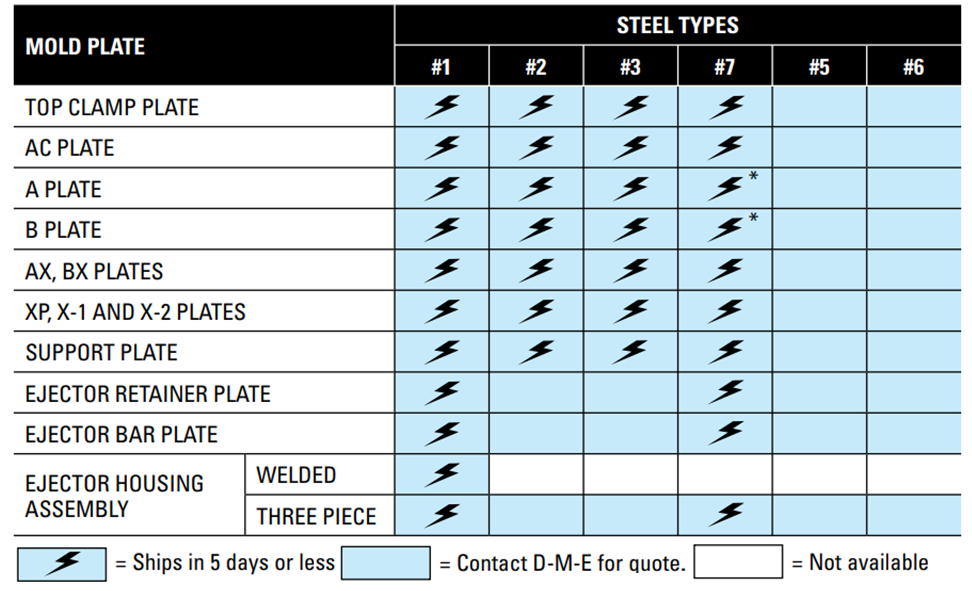

DME #2 Steel is a medium alloy steel specified for durability in structural applications. It is supplied pre-heat treated to 28-34 HRC (271-321 Bhn). A high strength steel, it is ideal for cavity and core retainer plates, clamping plates and support plates in molds. International comparisons: DIN 1.2312 (40CrMnMoS 8 6), 1.7218 (25CrMo4) and 1.2331 (41CrMoS4); JIS SCM 430; ISO 683-2 Type 1

DME #7 Steel is a modified AISI 400 series stainless steel for holder block applications. It is supplied pre-heat treated to 32-36 HRC (302-340 Bhn). This stainless steel offers corrosion-resistance and exceptional machinability but cannot be further hardened (see D-M-E #6). For humid environments, corrosive plastics, “clean room” or “100% stainless” applications, it is an ideal choice for all structural mold plates. International comparisons: none

D-M-E #5 Steel is an AISI/SAE H-13 type thermal shock resistant, hotwork die steel. Supplied fully annealed (approximately 200 Bhn; 13-20 HRC) for easy machinability, it can be subsequently heat treated to the desired hardness with a minimum of deformation. Mainly used for die cast dies, it is also suitable for plastic molds with exceptional hardness or

polishability requirements. D-M-E #5 Steel meets or exceeds the acceptance criteria established by the NADCA as detailed

in Technical Digest Number 01-80-01D. International comparisons: DIN 1.2344 (X40CrMoV5-1); JIS SKD 61; ISO 4955 H13

polishability requirements. D-M-E #5 Steel meets or exceeds the acceptance criteria established by the NADCA as detailed

in Technical Digest Number 01-80-01D. International comparisons: DIN 1.2344 (X40CrMoV5-1); JIS SKD 61; ISO 4955 H13D-M-E #6 Steel is a modified AISI 420 type stainless steel. It is supplied fully annealed to 179-241 Bhn (18-23 HRC), making it readily machinable. Unlike D-M-E #7 steel, D-M-E #6 steel is a cavity-grade material that can be subsequently heat treated to the desired hardness and has excellent polishability. International comparisons: DIN 1.4028 (X30Cr13); JIS SUS 420 J 2; ISO none

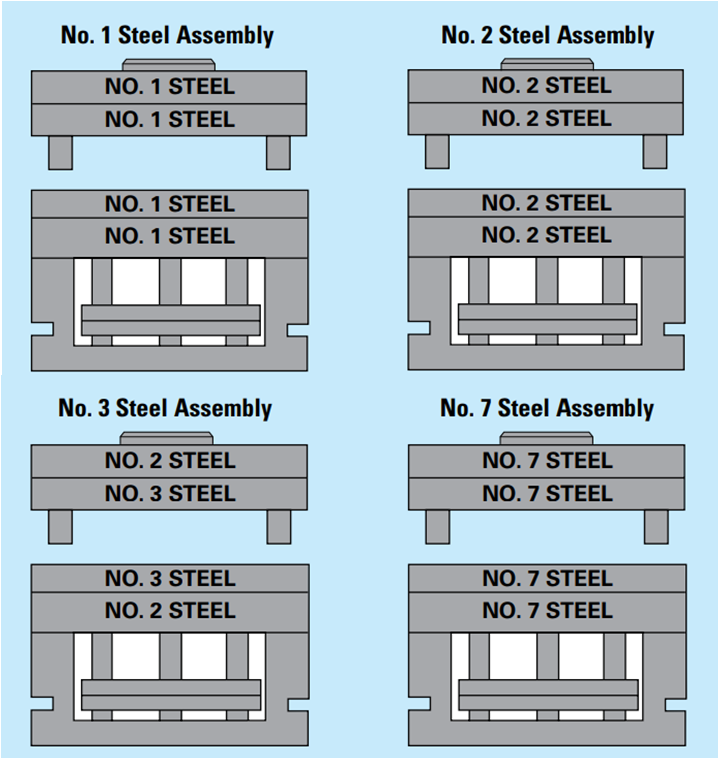

DME regularly mixes steel types within a mold base assembly to deliver plates configured to your application requirements. You can select steel types for each plate, as available from the table at left, in any combination for your mold base

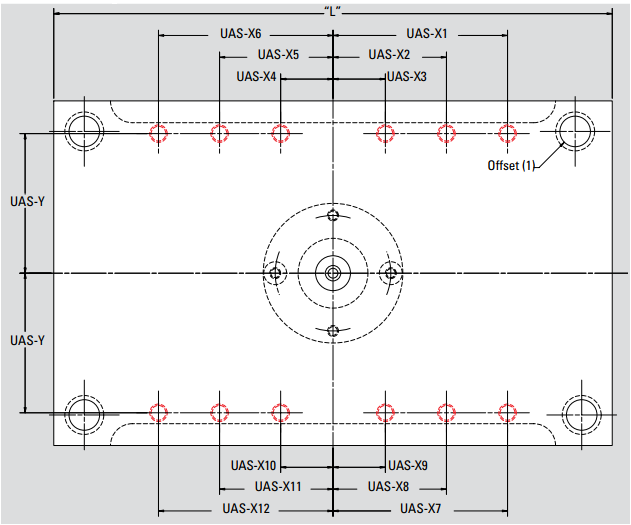

The item numbers for Standard Mold Bases in the A and B Series combine the NOMINAL Size (width and length), DME standard A series 7-7/8 mold bases

DME standard A series 9-7/8 mold bases

DME standard A series 10-7/8 mold bases

DME standard A series 11-7/8 mold bases

DME standard A series 13-3/8 mold bases

DME standard A series 14-7/8 mold bases

DME standard A series 15-7/8 mold bases

DME standard A series 16-1/2 mold bases

DME standard A series 17-7/8 mold bases

DME standard A series 19-1/2 mold bases

DME standard A series 23-3/4 mold bases

the Series (A or B) and the thicknesses of the A (or A -Clamping) and B Plates. Since all the standard mold plate thicknesses are acombination of a whole number and either 3/8 or 7/8, the designation 13 indicates 1 and 3/8; 17 indicates 1 and 7/8; 23 indicates 2 and 3/8, etc. For Example: 1016A-13-37 is the item number for a 97/8 × 16 A Series Mold Base with A plate 13/8 and B plate 37/8 thick.

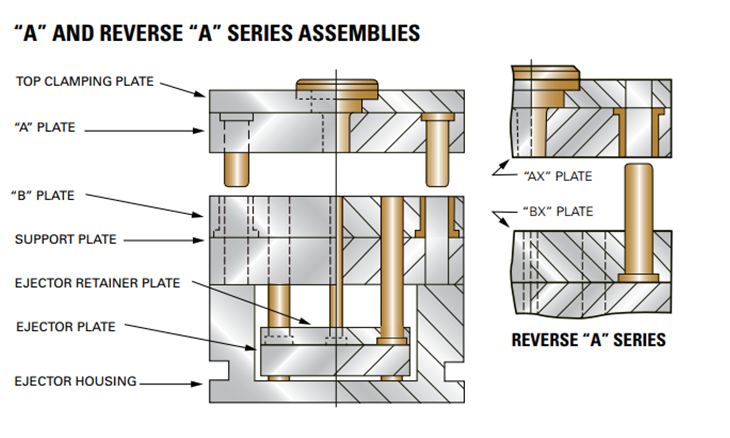

The most frequently used Standard Assembly,the

“A” Series Mold Base

is available in 43 sizes from 7 7/8 × 7 7/8 to 23 3/4 × 35 1/2. See pages 50-135 for complete information

The most frequently used Standard Assembly,the

“A” Series Mold Base

is available in 43 sizes from 7 7/8 × 7 7/8 to 23 3/4 × 35 1/2. See pages 50-135 for complete informationIdentical to the A Series, with leader pins and bushings reversed.Specify AX and BX plate thicknesses when ordering (rather than A and B).

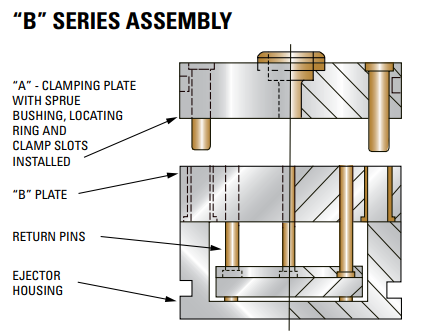

When cavities and cores are to be inserted into blind pockets, or machined directly into the A and B plates, the B Series Assembly is used. The Top Clamping Plate and Support Plate are omitted from the assembly.

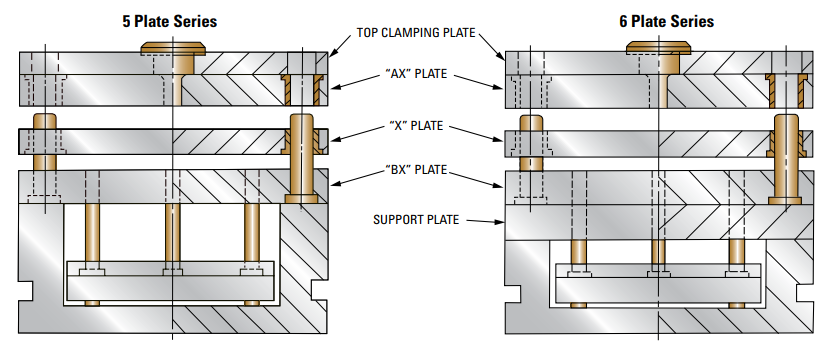

Most frequently used for molds requiring stripper plate ejection, the X Series Assembly is available with a Support Plate (6-plate series) or without a Support Plate (5-plate series)

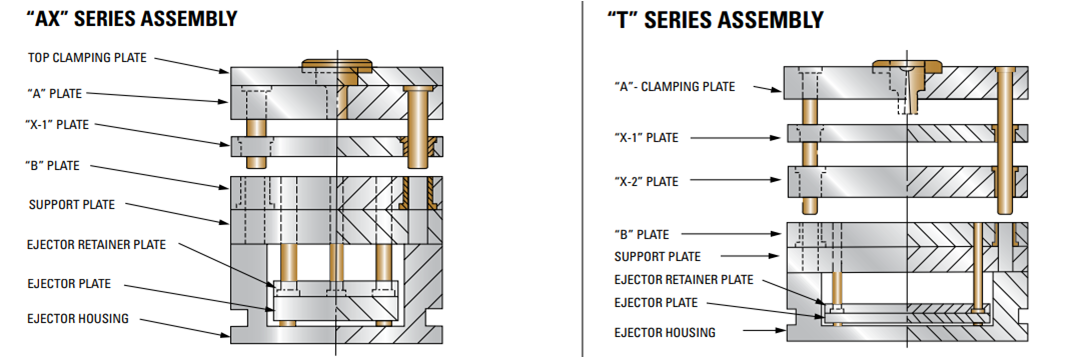

The item numbers for the “AX” Series Mold Bases combine the NOMINAL Size (width and length), the letters “AX” and the thickness of the “A” and “B” plates. The “X-1” plate thickness is specified when ordering and is omitted from the item number.

For Example: 1212AX-13-37 is the item number for an 117/8 × 12 AX Series Mold Base with a 13/8 thick A plate and 3-7/8 thick B plate. The X-1 plate thickness (e.g. 7/8) is then specified when ordering.The item numbers for the “T” Series Mold Bases combine the NOMINAL Size (width and length), the letter “T” and the thickness of the X-2 and B plates

Since the thickness of the A -Clamping plate is constant at 17/8 or 23/8 and the X-1 plate thickness is constant at 7/8 or

13/8, depending on the nominal size of the mold base, these thicknesses are not represented in the item number

Since the thickness of the A -Clamping plate is constant at 17/8 or 23/8 and the X-1 plate thickness is constant at 7/8 or

13/8, depending on the nominal size of the mold base, these thicknesses are not represented in the item numberFor Example: 1012T-23-17 is the item number for a 97/8 × 117/8 T Series Mold Base with a 23/8 thick “X-2” plate and 17/8 thick B plate. (In this case, the “A”-Clamping plate is 17/8 thick and the “X-1” plate is 7/8 thick)

The “AX” Series Assembly is used when the mold requires a floating plate to remain with the upper or stationary half of the assembly. It is basically an A Series Assembly with a floating plate ( X-1 ) added

The “T” Series Assembly is used for top runner molds that require two floating plates (“X-1” — runner stripper plate, “X-2” — cavity plate) to remain with the upper or stationary half of the assembly.

For Example: 1215-33-47 is an 11-7/8 × 15” Cavity Retainer Set with “A” plate 33/8 and “B” plate 47/8 thick.

For additional operator safety, DME mold bases include an ejector housing cover, except when a longer length ejector bar is selected. The perforated D-M-E logo helps the operator to visually determine if the ejector plate and ejector retainer plate are in the returned position. The cover is fastened on both sides with 5/16-18 button-head cap screws. Once again, D-M-E is leading the industry into a safer work environment.

Includes comparably sizedretainer sets and mold plates

Includes D-M-E #7 stainless steel in the A-Series mold base program (all plates and housing are stainless steel)

With the ever-growing need for just-in-time deliveries, this expansion of the D-M-E QDS program can greatly enhance your competitive edge

Ejector bar same length as mold base Any standard leader pin length desired

AX-Series Mold Bases T-Series Mold Bases, Cavity Retainer Sets

D-M-E #7 steel from 7/8" thick to 27/8" thick

1-piece or 3-piece housing (standard D-M-E rails)

Ejector housing covers, Relocate or omit return pins, Relocate or omit assembly screws (top and/or bottom)

Relocate or omit assembly screws in ejector set, Relocate or omit leader pins and bushings, Relocate or omit center holes

Relocate or omit stop pins in ejector bar, Sprue puller pin of your choice,

Machining for all D-M-E sprue bushings and most clamp slots, Machining for most locating rings

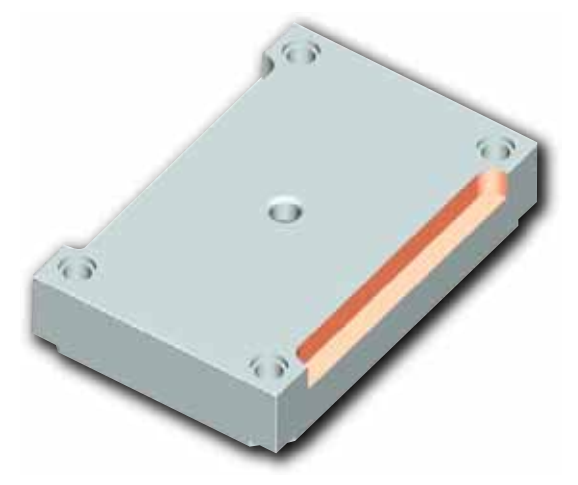

Consistent machining allowance throughout the surface of the cavity block provides even finishing without areas of heavy stock

D-M-E can provide customers with the CAM program to continue the work where D-M-E left off, saving time and programming expense

Contour roughing can be bundled with the option to stress-relieve cavity blocks and a custom mold base

The Contour Roughing Service begins with complex core and cavity CAD files from customers

D-M-E programs 3D cavity roughing tool paths that generate a rough milled surface, allowing machining stock for finishing by the customer

D-M-E uses industry-leading CAM software for programming contour roughing tool paths leaving consistent machining allowance throughout the surface of the cavity block

D-M-E has supported moldmakers, processors and designers around the globe since it innovated the standard mold base in 1942. Today, we offer the industry’s broadest range of market-leading products. In a recent Moldmaking Industry Survey, moldmakers said they needed an edge to better compete. That’s why our full featured, ready-to-ship mold base is called the Edge. Essentially, moldmakers named it for us! The Edge gives you the competitive and profitability advantages that D-M-E customers demand.

As you continue to positively impact your operations through process efficiencies, technology enhancements, and automation improvements, the D-M-E Edge Mold Base is with you every step of the way by providing the value, speed and exceptional quality that customers have long expected from the industry’s standard-setter in mold technologies. Even our competitors look to us as standard-setters; so much so, that today, competitors still promote their products by comparing them to ours

Get the Edge Mold Base and you’ll have another ingredient for the formula for a successful, growing business, and a partnership with the global mold technologies leader

The lowest-priced mold base on the market

Most sizes available for same-day shipment

Seven popular mold base features Reliable D-M-E quality-assured services, including manufacturing, inspection and distribution

Pry slots installed on both sides of “B” plate

Lift holes installed

Return pins installed 0.125 inboard to allow for spring pockets

Leader pin vents machined in the housing under the bushing location

Guided ejection installed

Three-piece ejector housingCenter hole machining included

NOTE: See Standard & Optional Mold Base Features section for specifications regarding Edge Mold Base features.