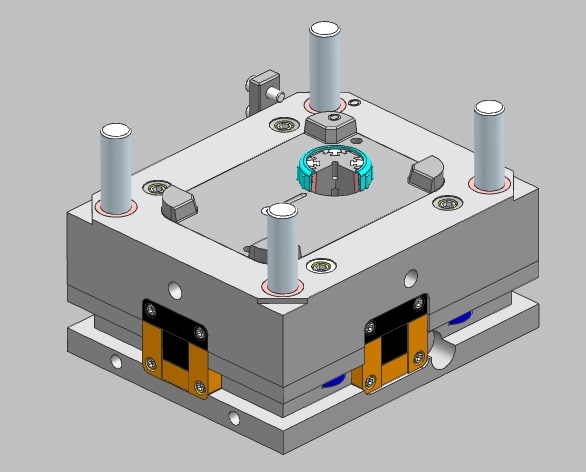

Viewmold has rich experiences for unscrewing injection mold, and provide very reliable and long lasting molds that can increase your speed,

productivity with higher cavitations and shorter cycle times.

Unscrewing injection mold has complex structure. In Chinese side, 50% unscrewing injection mold project aren't successful.

If you have any unscrewing injection mold project, you should contact us as soon as possible by email or

submit a quote online.Our first engineers has professional knowledge

and a lot of experiences for unscrewing injection mold structure,can provide you professional advice,

It also is a chance that you can get high quality unscrewing injection molds and make your project success.

Unscrewing plastic molds are typically utilized for high volume threaded plastic parts. Most threaded plastic parts on molds can't be removed by

standard knock-off techniques. Therefore unscrewing structure is utilized to prevent the threads on threaded parts from being damaged

while the parts are leaving the injection molds. Because the volume of threaded plastic parts need very high,the unscrewing molds will run as a

very fast speed to reduce cycle times thus reducing part costs,the quality of unscrewing plastic molds must be very high,the structure also must

be very relible.

There are more structure for unscrewing, it is very important to select suitable structure:

collapsible cores

Viewmold has rich experiences for unscrewing injection mold, and provide very reliable and long lasting molds that can increase your speed,

productivity with higher cavitations and shorter cycle times.

Unscrewing injection mold has complex structure. In Chinese side, 50% unscrewing injection mold project aren't successful.

If you have any unscrewing injection mold project, you should contact us as soon as possible by email or

submit a quote online.Our first engineers has professional knowledge

and a lot of experiences for unscrewing injection mold structure,can provide you professional advice,

It also is a chance that you can get high quality unscrewing injection molds and make your project success.

Unscrewing plastic molds are typically utilized for high volume threaded plastic parts. Most threaded plastic parts on molds can't be removed by

standard knock-off techniques. Therefore unscrewing structure is utilized to prevent the threads on threaded parts from being damaged

while the parts are leaving the injection molds. Because the volume of threaded plastic parts need very high,the unscrewing molds will run as a

very fast speed to reduce cycle times thus reducing part costs,the quality of unscrewing plastic molds must be very high,the structure also must

be very relible.

There are more structure for unscrewing, it is very important to select suitable structure:

collapsible cores

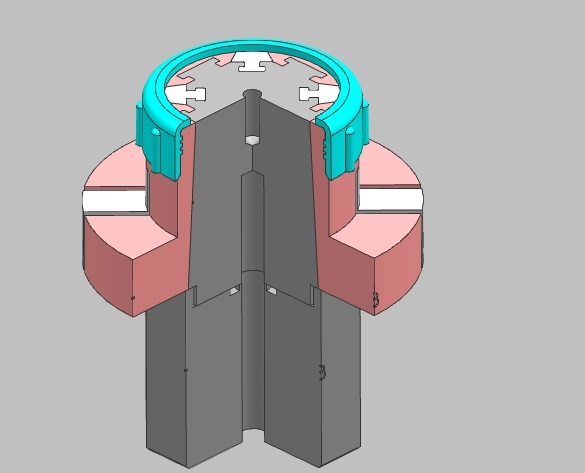

collapsible cores structure has more advantages:

1:The structure is simple.

2:production cycle time is shorter, because the structure doesn't need rotating action, it save more time.

3:The structure is suitalbe for any kind of thread or undercut.

4:The structure is specially suitable for the thread of bigger diameter

defects:

1:The thread of part must be more than 30MM.

2:The structure need precise manufacture

collapsible cores structure has more advantages:

1:The structure is simple.

2:production cycle time is shorter, because the structure doesn't need rotating action, it save more time.

3:The structure is suitalbe for any kind of thread or undercut.

4:The structure is specially suitable for the thread of bigger diameter

defects:

1:The thread of part must be more than 30MM.

2:The structure need precise manufacture

Unscrewing Injection Mold