ViewMold Co Ltd is an ISO 9001:2000 certified plastic injection molds company that supplies

plastic injection molds

plastic injection molds design

plastic injection molds manufacturing of high quality,plastic injection molding...

We are Proud to bring to you the quality and speed you would expect from Viewmold plastic injection molds. We believe we will be your supplier of choice. Just give Viewmold a

email or

submit a quote online.

Our team of quote specialists is the most responsive and the most hands on.

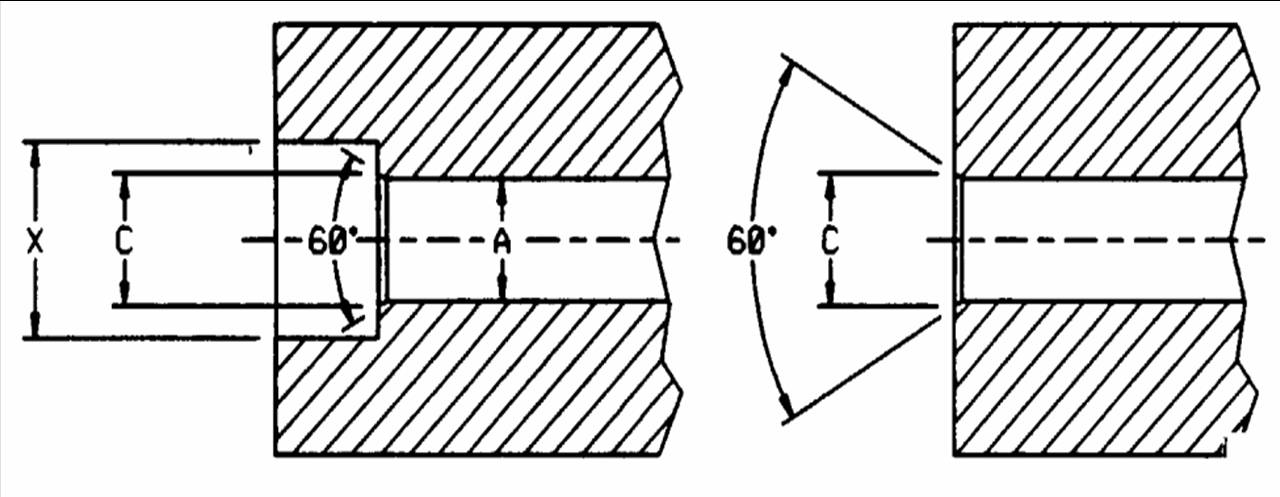

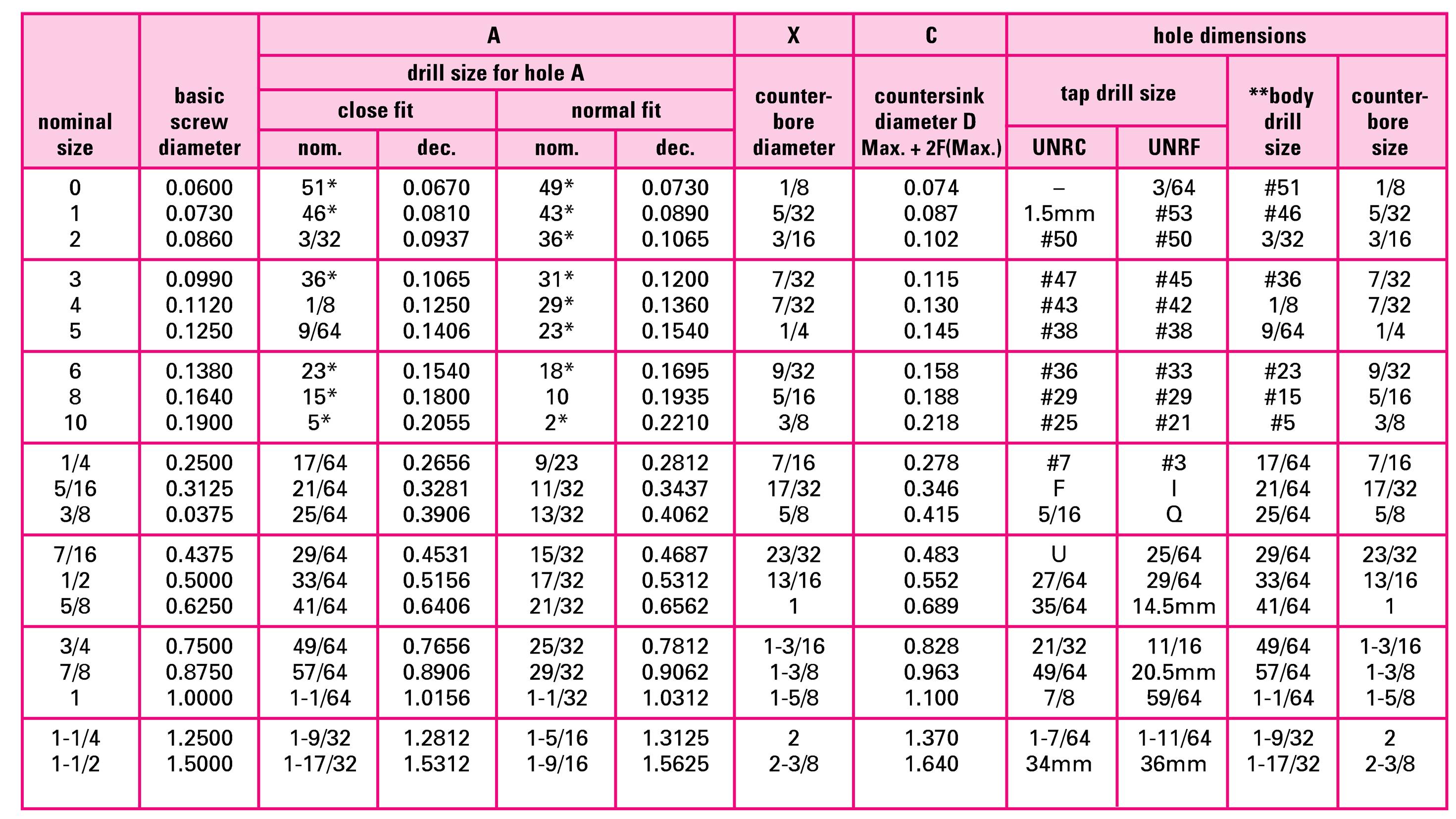

DRILL AND COUNTERBORE SIZES FOR INCH SOCKET HEAD CAP SCREWS

Note 1

Close Fit: Normally limited to holes for those lengths of

screws threaded to the head in assemblies in which: (1)

only one screw is used; or (2) two or more screws are

used and the mating holes are produced at assembly or

by matched and coordinated tooling.

Note 2

Normal Fit: Intended for: (1) screws of relatively long

length; or (2) assemblies that involve two or more screws

and where the mating holes are produced by conven-

tional tolerancing methods. It provides for the maximum

allowable eccentricty of the longest standard screws and

for certain deviations in the parts being fastened, such as

deviations in hole straightness; angularity between the

axis of the tapped hole and that of the hole for the shank;

differneces in center distances of the mating holes and

other deviations.

Note 3

Chamfering: It is considered good practice to chamfer or

break the edges of holes that are smaller than "F" max

mum in parts in which hardness approaches, equals or

exceeds the screw hardness. If holes are not chamfered,

the heads may not seat properly or the sharp edges may

deform the fillets on the screws, making them suscepti-

ble to fatigue in applications that involve dynamic load-

ing. The chamfers, however, should not be larger than

needed to ensure that the heads seat properly or that the

fillet on the screw is not deformed. Normally, the cham-

fers do not need to exceed "F" maximum. Chamfe

exceeding these values reduce the effective bearing area

and introduce the possibility of indentation when the

parts fastened are softer than screws, or the possiblity of

brinnelling of the heads of the screws when the parts are

harder than the screws. (See "F" page 6