STRIPPING STRENGTH OF TAPPED HOLES

Charts and sample problems for obtaining minimum

thread engagement based on applied load, material,

type of thread and bolt diameter.

Knowledge of the thread stripping strength of tapped holes is necessary to develop full tensile strength of the bolt or, for that matter, the minimum engagement needed for any lesser load.

Conversely, if only limited length of engagement is available, the data help determine the maximum load that can be safely applied without stripping the threads of the tapped hole.

Attempts to compute lengths of engagement and related factors by formula have not been entirely satisfactory-mainly because of subtle differences between various materials. Therefore, strength data has been empirically developed from a series of tensile tests of tapped specimens for seven commonly used metals including steel, aluminum, brass and cast iron.

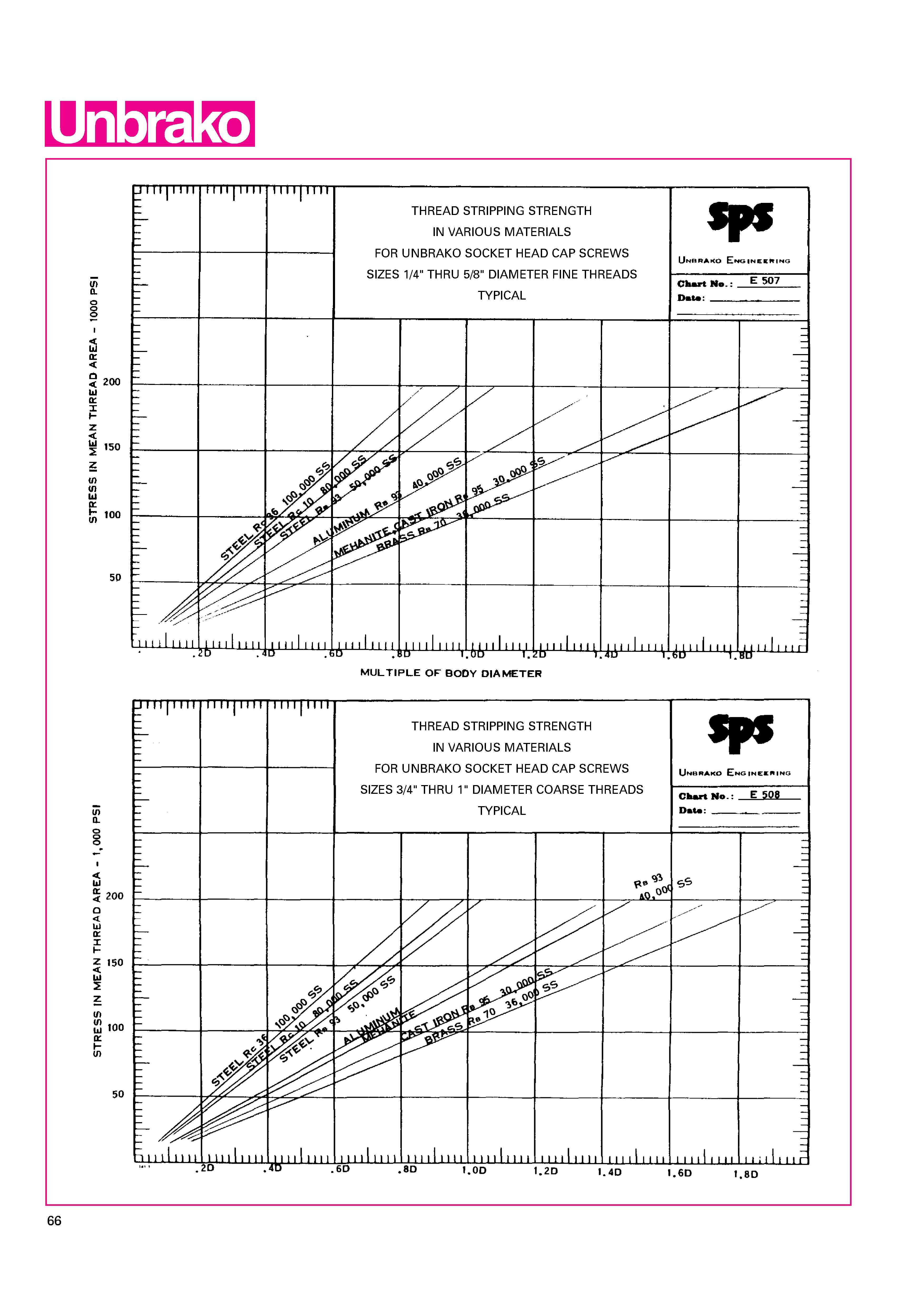

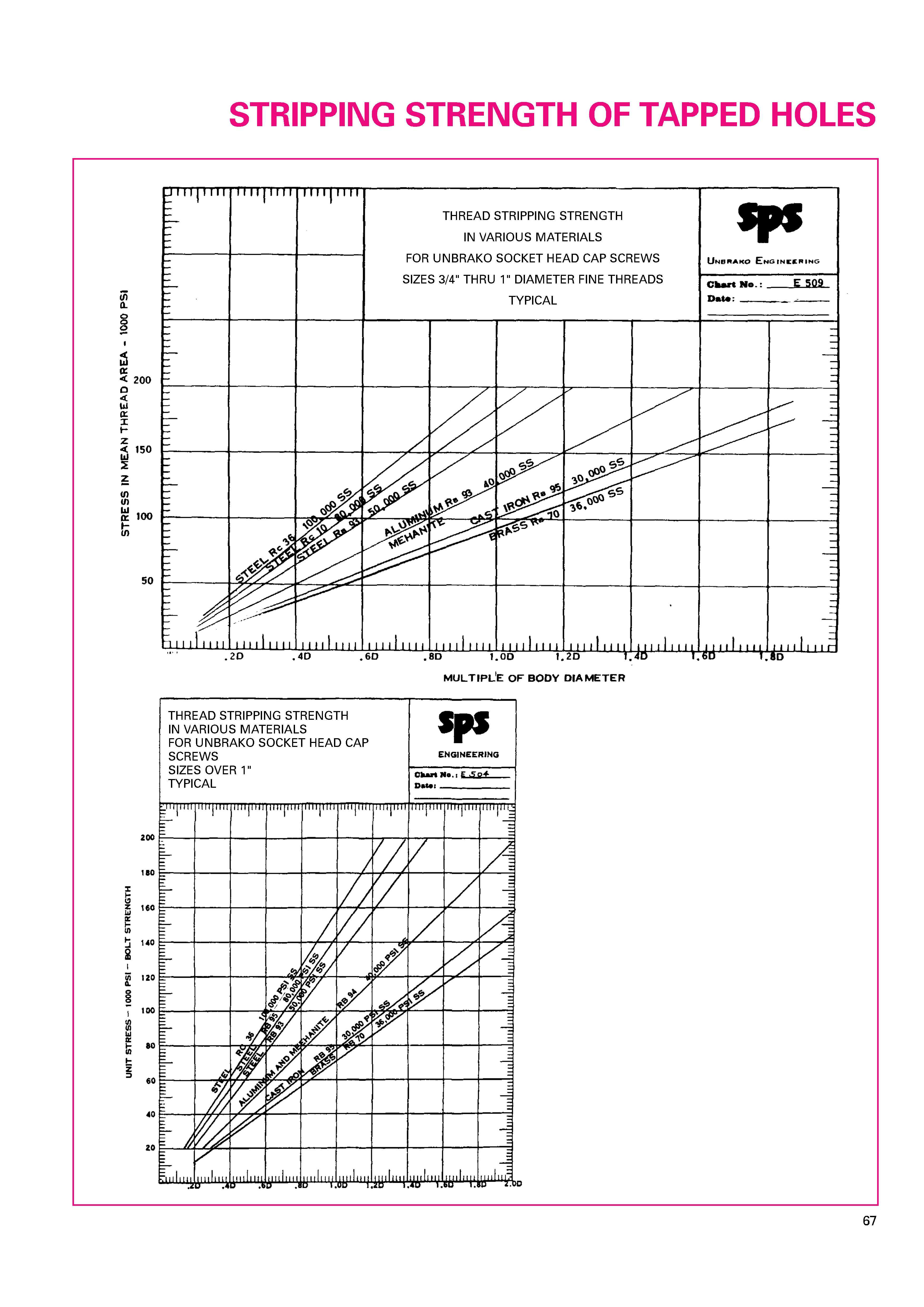

The design data is summarized in the six accompanying charts, (Charts E504-E509), and covers a range of screw thread sizes from #0 to one inch in diameter for both coarse and fine threads. Though developed from tests of Unbrako socket head cap screws having minimum ultimate tensile strengths (depending on the diameter) from 190,000 to 180,000 psi , these stripping strength values are valid for all other screws or bolts of equal or lower strength having a standard thread form. Data are based on static loading only.

In the test program, bolts threaded into tapped specimens of the metal under study were stressed in tension until the threads stripped. Load at which stripping occurred and the length of engagement of the specimen were noted. Conditions of the tests, all of which are met in a majority of industrial bolt applications, were:

Tapped holes had a basic thread depth within the range of 65 to 80 per cent. Threads of tapped holes were Class 2B fit or better.

Minimum amount of metal surrounding the tapped hole was 2 1/2 times the major diameter.

Test loads were applied slowly in tension to screws having standard Class 3A threads.(Data, though, will be equally applicable to Class 2A external threads as well.)

Study of the test results revealed certain factors that greatly simplified the compilation of thread stripping strength data:

Stripping strengths are almost identical for loads applied either by pure tension or by screw torsion. Thus data are equally valid for either condition of application.

Stripping strength values vary with diameter of screw. For a given load and material, larger diameter bolts required greater engagement.

Minimum length of engagement (as a percent of screw diameter) is a straight line function of load. This permits easy interpolation of test data for any intermediate load condition.

When engagement is plotted as a percentage of bolt diameter, it is apparent that stripping strengths for a wide range of screw sizes are close enough to be grouped in a single curve. Thus , in the accompanying charts, data for sizes #0 through #12 have been represented by a single set of curves.

With these curves, it becomes a simple matter to determine stripping strengths and lengths of engagement for any condition of application. A few examples are given below:

Example 1. Calculate length of thread engagement necessary to develop the minimum ultimate tensile strength (190,000 psi) of a 1/2(R)C13 (National Coarse Unbrako cap screw in cast iron having an ultimate shear strength of 30,000 psi. E505 is for screw sizes from #0 through #10; E506 and E507 for sizes from 1/4 in. through 5/8 in.; E508 and E509 for sizes from 3/4 in. through 1 in. Using E506 a value 1.40D is obtained. Multiplying nomi- nal bolt diameter (0.500 in.) by 1.40 gives a minimum length of engagement of 0.700 in.

Example 2. Calculate the length of engagement for the above conditions if only 140,000 psi is to be applied. (This is the same as using a bolt with a maximum tensile strength of 140,000psi.) From E506 obtain value of 1.06D Minimum length of engagement = (0.500) (1.06) = 0.530. Example 3. Suppose in Example 1 that minimum

length of engagement to develop full tensile strength was not available because the thickness of metal allowed a tapped hole of only 0.600 in. Hole depth in terms of bolt dia. = 0.600/0.500 = 1.20D. By working backwards in Chart E506, maximum load that can be carried is approxi- mately 159,000 psi.

Example 4. Suppose that the hole in Example 1 is to be tapped in steel having an ultimate shear strength 65,000 psi. There is no curve for this steel in E506 but a design value can be obtained by taking a point midway between curves for the 80,000 psi and 50,000 psi steels that are listed. Under the conditions of the example, a length of engagement of 0.825D or 0.413 in. will be obtained.